The industrial CT technology in the aerospace field reaches a new pinnacle with the successful maiden flight of the C919 commercial aircraft, leading the innovation in the aerospace industry's CT applications.

Whether application-oriented scientific achievements can be successfully transformed into scientific and technological products that serve society and promote social development are an important criterion for judging the level of national science and technology development and comprehensive strength. Civil aviation passenger aircraft is an integrated product of countless high-tech technology, which has high requirements for the scientific and technological strength and industrial level of a country.

On May 28, 2023, the commercial flight of the domestic large passenger aircraft C919 was successful. This is the extremely important "first time" in the history of the development of Chinese civil aviation, which has affected the hearts of the people of hundreds of millions of people across the country. The aerospace field has high requirements for flight safety. In order to achieve such a "first time" and ensure continuous and safe operation in the future, it is inseparable from the reliable and efficient non-destructive inspection methods to ensure the structure integrity and the quality of aviation devices of the aircraft. In this regard, industrial CT technology is playing an increasingly important role.

Industrial CT technology, as an advanced non-destructive detection method, has the characteristics of non-destructiveness, high resolution, and three-dimensional reappearance. It can be widely used in the ion of various materials and components in the aerospace field. Compared with traditional non-destructive inspection methods (such as ultrasonic detection, magnetic powder detection, vortex detection, etc.), only the problem with the superficial surface or accuracy of the object can only be inspected. Industrial CT can provide a comprehensive and high-precision internal structure information, help inspection and evaluation hides in hiding in the hidden in Internal defects of the parts, and the industrial CT does not need to use the medium such as coupling agent, magnetic powder, etc., it has no requirements for conductivity for internal materials. It is more common and easier to apply. The three-dimensional imaging and analysis function of the industrial CT can also perform wall-thick analysis, defect statistics, coordinate measurement and other testing of components of complex shapes to escort the quality of the product and ensure the safety and stability of aerospace.

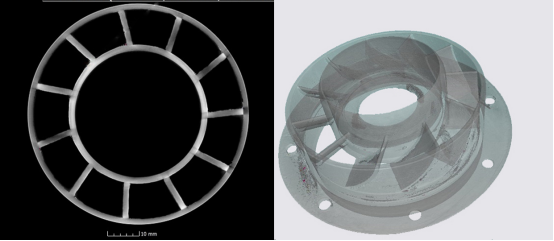

Size Accuracy Measurement

The complex components of aerospaces usually count in "million". In the case of ensuring the high precision of parts, it is necessary to ensure its high sealing properties, and the size and accuracy of the components under the huge order of magnitude is also crucial. The industrial CT can see the axis, the piston, and the inside of each valve by measuring the single parts of the aircraft engine, and measure the key size and geometric characteristics of the components without disassembling the engine. The degree of coordination between them ensures its accuracy and stability in the assembly process.

Figure 1: 3D analysis of aviation 3D printing structure

Internal Defect Inspection

The aerospace field has high requirements for component defects, and any tiny defect or damage may have a significant impact on the performance and reliability of the entire system. Industrial CT inspection technology can detect and analyze the defects, cracks, pores and other problems of internal and external parts, improve the controllability of the manufacturing process and the quality of the product. Wait for parts and components to produce and repair and maintenance in service aircraft.

Figure 3: High-temperature alloy turbine disk

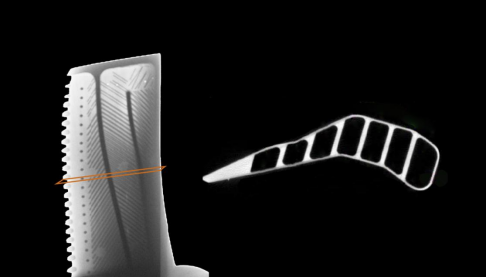

Wall Thickness Analysis

Industrial CT can accurately measure the wall thickness of aerospace key components, such as engine components, fuel pipelines, aircraft structures, composite material thickness, etc., and automatically find areas with insufficient wall thickness or insufficient gap width or excess.

Figure 4: Leaf wall thickness detection

Materials Analysis

Industrial CT technology can be used to accurately measure key features such as the density and pore rate of the material. It can evaluate the uniformity and consistency of the material, and inspect the signs of the failure of foreign bodies or materials that may exist.

Figure 5: Raw material powder test: powder internal structure, powder size assessment

The development and innovation of industrial CT technology are bringing new breakthroughs to the aerospace field. The high customization of the industrial CT, the ability to adapt to the customer's workflow, and the application of artificial intelligence inspection software, enable the industrial CT to meet the complex and diversified inspection requirements in the aerospace field, and provide efficient, reliable and automated inspection solutions Essence

High customization: parts and components in the field of aerospace usually have unique shapes, sizes and material characteristics. It is difficult for a single technical characteristics to meet the needs of diversity. If the industrial CT can be highly customized in the ray source, the inspector, and the scanning method, it will better meet the detection needs of different parts and components and obtain the best test results.

Adapted customers' workflow: The aerospace field has strict quality control and process requirements, and the workflows that match it are extremely complicated and diverse. If the industrial CT can be closely concentrated with the customer's workflow, it will better ensure the efficiency and repetitiveness of the inspection process, and achieve comprehensive quality management and traceability. This ability to adapt to the customer's workflow makes the industrial CT a seamless inspection solution in the aerospace field.

Artificial intelligence inspection software: With the development of artificial intelligence and machine learning, industrial CT combined with AI inspection software can provide automated defect inspection and analysis to improve the efficiency and accuracy of inspection. It can identify and classify different types of defects by training models, and achieve automated defect assessment and report generation. In the field of aerospace, this AI detection software can greatly reduce the needs of manual intervention. While improving the consistency and reliability of inspection, it improves inspection efficiency and reduces labor costs.

The successful commercial flight of domestic large -scale passenger aircraft C919 is an iconic event in the history of Chinese civil aviation. With the successful progress of C919's commercial operations, how to ensure its safe operation will become a continuous concern. The continuous development and innovation in the field of industrial CT technology will work with the changes in the field of civil aviation to cope with changing quality control challenges.

English

English